how to read vickers hardness test|vickers hardness test pdf : import The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter can be used for all materials irrespective of h. Mais de 465 imóveis à venda em Itapetininga, São Paulo. Acesse as melhores ofertas de imóveis à venda por imobiliárias e proprietários em Itapetininga. Imóveis à venda em Itapetininga, SP por Imobiliárias e Proprietários - Viva Real

{plog:ftitle_list}

Resultado da O gerador de RG tem o intuito de ajudar e facilitar a vida de estudantes, programadores, analistas e testadores. Essa ferramenta normalmente se faz válida para testes de softwares. Os documentos são gerados de forma aleatória, respeitando o algoritmo para a validade de um RG. O gerador .

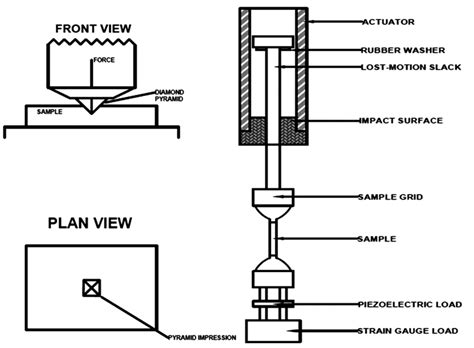

vickers hardness testing machine diagram

how to test for soft tissue damage

vickers hardness test theory

Vickers hardness testing is a common and widely used method for determining the hardness of a material. It measures the depth of penetration of a diamond indenter under . What is the Vickers Hardness Test. NextGen explains the machine, its applications and the necessary consumables required for the Vickers Hardness Testing needs.The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter can be used for all materials irrespective of h.

The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 .The Vickers hardness test is a method of measuring the hardness of a material by indenting it with a diamond indenter in the shape of a right pyramid with a square base and an angle of .This Vickers hardness number calculator uses the size of indentation to return the hardness of the material. There are different scales to measure hardness, including Brinell hardness, Rockwell hardness, Meyers hardness, and Vickers .

Vickers and Knoop hardness test principle: An indentation hardness test using a verified machine to force an indenter, under specified conditions, into the surface of the material under . Basic principle and practical procedure of the Vickers hardness test - Testing machine, test piece, diamond pyramid indenter - Basic principle, hardness de.

how to test for soft tissue sarcoma

How to read and represent a Vickers hardness value. Advantages and disadvantages of the Vickers method. The Vickers method has the following advantages: The Vickers method can be used with any and all materials and .The Vickers method has the following advantages: The Vickers method can be used with any and all materials and test specimens, from soft to hard, as the procedure covers the entire hardness range.Hardness tests measure the resistance of a material against plastic deformation.To perform these tests (be it Brinell, Rockwell, or Vickers), an indenter is pressed on the surface of the specimen with a specific force F F F .For the Vickers hardness test, the measured diagonals should not deviate more than 5.0% from each other. For the Knoop hardness test, the two halves of the long diagonals must not differ by more than 10.0% from each other. . If the specimen is not properly cleaned after mechanical preparation and you perform an optical reading of the hardness .

The Vickers hardness test is demonstrated along with the Excel calculator. The calculator is available to HVCC students at the link below.https://hvcc0-my.sh.The Rockwell scale is one of the standard methods used to measure a material's hardness. The scale has different numbers that represent hardness based on the indent's depth caused by the test material's indentation. Let us look at how you can measure and read Rockwell's hardness value in this article. Also, the Vickers tester measures hardness by the Vickers Hardness Value (symbolized as HV) or the Diamond Pyramid Hardness Value (or DPH). Another unique feature in Vickers tester is the usage of two unique parameters. A. Macro Hardness – These Vickers testers use loads ranging from 1kg to 100 kg. They are specifically designed to test hard .

Mohs hardness test: When conducting the test, place the unknown specimen on a table top and firmly hold it in place with one hand. Then place a point of the reference specimen against a flat, unmarked surface of the unknown specimen. Press the reference specimen firmly against the unknown, and deliberately drag it across the flat surface while pressing firmly.

Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion .

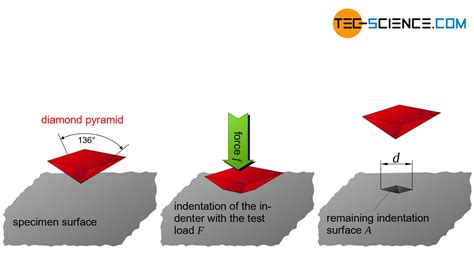

The Vickers hardness test method consists of indenting the test material with a diamond indenter, in the form of a right pyramid with a square base and an angle of 136 degrees between opposite faces subjected to a load of 1 to 100 kgf. The full load is normally applied for 10 to 15 seconds. The two diagonals of the indentation left in the .

Learn more about hardness testing basics here. The Vickers hardness test method, also referred to as a microhardness test method, is mostly used for small parts, thin sections, or case depth work. The Vickers method is based on an optical measurement system. The Microhardness test procedure, ASTM E-384, specifies a range of light loads using a .

Hardness generally refers to the resistance of a material to scratching or indentation, and a qualitative measure of the strength of the material. The most commonly used hardness tests are the Rockwell test, Brinell test and the Vickers hardness test. This article will provide an introduction into durometer hardness and the gauge used to . The Vickers hardness test can use a test force greater than 980.7N;2. The micro Vickers test force is recommended. Characteristics and Application of Vickers Hardness . and machine tools for metals. I am constantly thinking, reading, and writing about these subjects, constantly striving to stay at the forefront of my field. Let my knowledge .A method that can be used for figuring out a material’s hardness—a measurement of its resistance to deformation in the presence of force—is the Vickers hardness test. While it finds use in other materials like ceramics & some polymers, this test is widely employed in the metallurgical area.The Vickers hardness number (HV) is calculated based on the indentation diagonal lengths. This method is suitable for a wide range of materials, including metals, ceramics, and plastics. Due to its small indentation size the Vickers hardness test allows for testing on very thin materials and provides accurate results. Where: HV is the Vickers .

The Vickers test often has strict specimen requirements due to the high sensitivity of the optical reading instrument and the need to get an accurate result. This article provides what you need to know for adequate preparation of your specimen for an accurate Vickers hardness test.

It’s important that engineers specify hardness testing methods correctly to ensure timely heat treatment and avoid costly delays. Common hardness testing methods are introduced below. Rockwell Hardness. This .The Vickers hardness test measures the maximum load applied to an object without its deformation exceeding a specified value. To measure the hardness, a diamond indenter is pressed against a test sample, and a specified load is applied. The indent’s measurement is then used to calculate the value of Vickers hardness which is translated and . For the Vickers hardness test, a square base pyramid with a opening angle of 136° is used as the indenter (opening angle = angle between two opposite surfaces of the pyramid). The angle was chosen so that the Vickers hardness values are comparable to a certain degree with the Brinell hardness values (applies to approx. 400 HBW or 400 HV). The .

The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and understand the standard completely before attempting a Rockwell test. The Rockwell test is generally easier to perform, and more accurate than other types of hardness testing methods .The Vickers hardness test can be a micro indentation test and also for the macro hardness test. It is mainly divided into two steps. The test force (load) F is applied on the specified square base pyramid shaped diamond indenter for the specific time when it collides with the testing sample object in the direction normal to the test surface.

Basic principle and practical procedure of the Vickers hardness test - Testing machine, test piece, diamond pyramid indenter - Basic principle, hardness de.

3.2 Conducting the Test. Positioning the Sample: Secure the material sample in the testing machine.; Selecting the Indenter: Choose the appropriate ball diameter based on the material hardness.; Applying the Load: Gradually apply the specified load using the machine.The load should be maintained for a predetermined dwell time, usually between 10 to 15 seconds.

Hardness Conversion Formula. Y = aX^2 + bX + c. Where: Y is the hardness value in the target scale; X is the hardness value in the original scale; a, b, and c are constants determined through empirical testing; Example: Converting Brinell (HB) to Rockwell C (HRC) for steels:. HRC = -0.000000567 HB^2 + 0.0624 HB – 13.7. Using this formula, we can convert a Brinell hardness .

3. Vickers Hardness (HV) Vickers hardness is determined by pressing a diamond square cone with a 136° top angle and a load of up to 120kg into the material’s surface. The Vickers hardness value (HV) is calculated by dividing the load by the surface area of the indentation pit, expressed in kgf/mm². 4. Leeb Hardness (HLD) In addition, the hardness value can be read with no additional optical equipment, making it one of the most common hardness testing methods. The Rockwell test is described in ASTM E18 . Because the Vickers hardness test requires the use of optical and measuring equipment and material preparation, the cost tends to be higher than others .🕑 Reading time: 1 minute. The Vickers hardness test is a static hardness test method, used for both macro and microhardness testing. It is an optical method of testing where the size of the indentation left by the indenter is measured to determine the hardness value of a test specimen.

15.2.3.2 Hardness Test. A Vickers hardness testing machine was employed to determine the hardness differences of all the rolled strip specimens in the thicker, thinner, and transition zones by applying a load of 1 N with a dwelling time of 12 s. Hardness measurements were performed on the cross-section surfaces of the rolled strips along the .

XNXX Today's selection. This menu's updates are based on .

how to read vickers hardness test|vickers hardness test pdf